Xtraplus Abrasion™ Resistant Coated Agitators

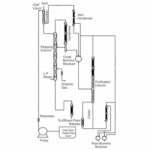

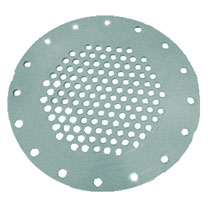

Xtraplus Abrasion™ Resistant Coated Column internals, packing, support, plates, Distributors

Xtraplus Abrasion™ Resistant Coated Hoppers

Xtraplus Abrasion ™ Coating gives Extreme Chemical resistance due to best permeation resistance along with very good abrasion resistance.

These coatings are highly resistance against chemicals like acids, alkalis, solvents etc. specially for polar solvents and has extra longer life compared to normal coating.

Xtraplus Abrasion™ Coating are manufactured by mixing special fillers with fluoropolymer powders. Fillers reduces permeation of chemicals through fluoropolymer film and improves chemical resistance & also improves abrasion resistance of fluoropolymers film.

Xtraplus Abrasion™ Coating are available as follows:

- PVDF

- ECTFE (HALAR)

- ETFE

- FEP

- PFA

Coating Thickness: Available from 600 microns to 1.5 mm thk.

Comparison of properties of Xtraplus Abrasion™ with normal fluoropolymers Coating.

Abrasion Resistance: The abrasion was determined by measuring loss of weight at 50° C using a roller abrasion instrument at an applied load of 1 N / mm², the sliding speed was 2 m/s.

| Fluropolymer | Abrasion in mg loss | |

|---|---|---|

| Normal | Xtraplus Abrasion™ | |

| PVDF | 60 | 11 |

| ETFE | 96 | 18 |

| PFA | 660 | 124 |

- Xtraplus Abrasion™ is Low permeation coating of PVDF, ECTFE, ETFE, PFA etc.

- Xtraplus Abrasion™ is Abrasion Resistant coating of PVDF, ECTFE, ETFE, PFA etc.

- Xtraplus Abrasion™ Coating Gives Longer Life for corrosion application.

Thus Xtraplus Abrasion ™ coating gives longer life in chemical use compared with normal Fluropolymer coating due to improvised permeation and abrasion resistance.

Application of Xtraplys Abrasion™ coating:

- Agitator

- Column internals packing support plates, Distributors

- Hoppers

- Reactors

- Pump impeller and casing