HDPE / PP / PVDF / HALAR Coated Centrifuge

MS/HALAR COATED CENTRIFUGE

MS/HALAR COATED LIFTING BAG TYPE CENTRIFUGE

DPE / PP / PVDF / HALAR COATED CENTRIFUGE

FLUOROPOLYMER COATED CENTRIFUGE

MS/HALAR COATED LIFTING BAG TYPE CENTRIFUGE :

HDPE / PP / PVDF / HALAR Coated Centrifuge is used for handling corrosive chemicals for separating solids from slurry (mixture of Solid & Liquid), Sulphuric Acid, Nitric Acid, Bromic Acid and Low Concentration of Solvent like Benzene, Toluene, Heptane, Hexane Etc.

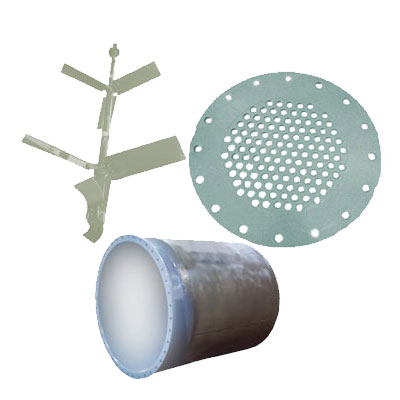

Manual Top Discharge Centrifuge :

One of the simplest type of centrifuge widely used in industry. Solid material is scooped out manually from the top of the centrifuge. Outer Body can be Full Body opening type for easy cleaning of centrifuge. Full Lid opening also available for easy cleaning and maintenances, 4 pt mounting with Inertia Plate & Anti-Vibration Mounts.

Bag Lifting Top Discharge Centrifuge:

This type of centrifuge is an improvement on the basic Manual Top Discharge Centrifuge. It has a conical shell of Basket for easy removal of Filter bag along with solid material from basket. It reduces solid material removal time and may increase production.

HDPE Coated Centrifuge is replacement of Rubber lined centrifuge as its chemicals resistance is better than Rubber.

MS / PP Coated Centrifuge is replacement of SS 316 centrifuge for some of the application.

PVDF Coated Centrifuge is replacement of HALAR Coated centrifuge as its having similar chemicals resistance and for handling Chlorinated & Brominates product better than HALAR.

HALAR Coated Centrifuge is used universally for API, Bulk drug and FDI applications.

All polymers are also available with antistatic properties having surface resistivity 10e4 to 10e8 Ohms per Sq.

POLYMER COATING SELECTION GUIDE

| Polymer | Compatibility & Application | Non - Compatibility |

| HDPE | Storage of Caustics, Metal Finishing Chemicals, Organic &In Organic Acids, Water Treatment Chemicals, Plating Chemicals & Brine FDA 21 CFR 177. 1520 | Strong Oxidizing Agents, Aromatic Hydro Carbons & Halogenated Aliphatic Hydro Carbons |

| PP | Suitable for many corrosive chemicals which are not suitable for FRP Storage of Sulfuric Acid, Hydrochloric Acid, Hydrofluoric Acid, Organic & In Organic Chemicals | Strong Oxidizing Agents & Halogenated Aliphatic Hydro Carbons |

| PVDF | Superior Resistance to Inorganic Acids, Strong Oxidizing Agents & Halogenated Chemicals FDA 21 CFR 177. 2510 | Ketones, Esters, Amines & Hot Concentrated Caustics |

| HALAR | Similar to PVDF but having better resistance to Ketones FDA 21 CFR 177. 2510 | Amines & Halogenated Hydro Carbons like MDC, EDC, Bromo Benzene |

| Polymer | Chemical Resistance | Stress Crack Resistance | Maximum Operating Temperature | Brittleness Temperature | Impact Resistance | FDA Applicability | Color |

| HDPE | Very Good | Good | Deg C | -70 Deg C | Good | Yes | Black |

| PP | Very Good | Excellent | 65 Deg C | -118 Deg C | Excellent | No | Offwhite |

| PVDF | Excellent | Good | 80 Deg C | -40 Deg C | Good | Yes | Brown |

| HALAR | Excellent | Good | 95 Deg C | -80 Deg C | Good | Yes | Green |