PFA Coated Aluminium / SS 316 Shell & Tube Heat Exchanger

Shell & Tube Heat Exchanger Coating for Corrosive Chemicals & Vapours.

- Excellent Chemical Resistence

- Safe Processes

- Excellent Thermal Conductivity

- Suitable for Fluorinated Chemicals

(A) Operating Condition:

Temperature - -50° to 200° C

Pressure : Full Vacuum to 5kg/cm2

Applications:

-

Liquid - Liquid cooling

Water - Water

Water - Solvent - Liquid - Gas Condensation

Water - Steam

Water - Solvent Vapour - Evaporation

Steam - Water

Steam - Solvent

(B) Area of Application:

- API Bulk Drugs

- Chemical Industries

- Multi Purpose Plant

- Sulfuric Acid Concentration Systems

- Nitric Acid Concentration Systems

- HCL Striper Systems

- HCLAzeo Breaker System

(C)

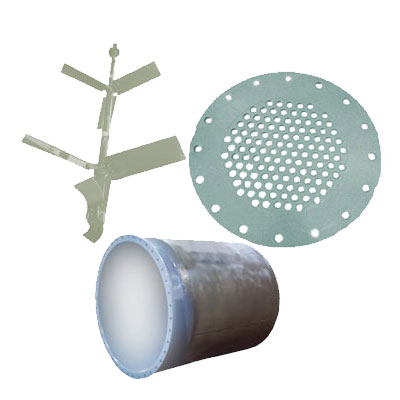

Tube:

- PFA Coated Aluminium

- PFA Coated SS 316

Shell:

- PFA Coated SS

- PFA Coated CS

- Glass

End Bonnet:

- SS 316

- Glass

Thermal conductivity of Aluminium is:

- 1.5 Times of Graphite

- 10 Times of Titanium

- 20 Times of Hastelloy

- 60 Times of Glass

Thermal conductivity of PFA Coated Aluminium is:

- Equal to Graphite

- 8 Times of Titanium

- 14 Times of Hastelloy

- 40 Times of Glass

Thermal conductivity of PFA Coated SS 316:

- Equal to Hastelloy

- 2 Times of Glass

(D) Construction of Shell & Tube Heat Exchangers

| DN | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| AREA M 2 | 0.5 to 1.5 | 1 to 3 | 1.5 to 5 | 3 to 9 | 4 to 12 | 5 to 15 | 6 to 18 | 7 to 21 | 9 to 27 |