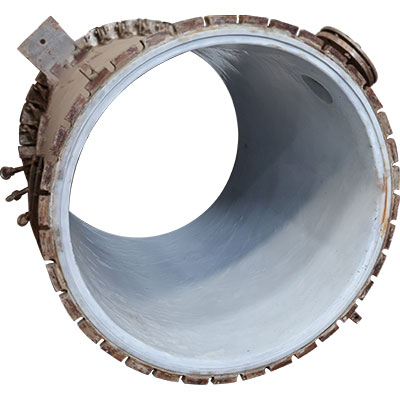

HDPE / PP / PVDF / ETFE / PFA / PTFE LINED DISTILLATION COLUMNS

MOC: MS IS 2062 or SS SA 304/316

LINING

- A. 1.5mm to 6mm thick seamless Roto Lining from Dia 200 to 2500mm & Max Length single piece Upto 5000mm.

- B. Upto 4mm thick welded sheet lining construction of any size & Length.

PVDF / PTFE Lined Columns and Tower With Structured Packing & Internals

PVDF / PTFE Lined Columns and Tower With Structured Packing & Internals

Fluoropolymers lined distillation columns and towers offer exceptional resistance to corrosion, making them ideal for various industries. With their unique properties, these columns provide a reliable and efficient solution for separating mixtures based on boiling points. The fluoropolymer lining ensures that the column remains unaffected by the harsh chemicals and high temperatures involved in the distillation process. This not only extends the lifespan of the column but also reduces maintenance costs. Additionally, the smooth surface of the fluoropolymer lining minimizes fouling and buildup, ensuring consistent performance and optimal efficiency.

We are leading manufacturer and supplier of PVDF/PTFE Lined Columns and Tower with Structured Packing, Random Packing, and Internals.

Applications:

- Bromine Recovery Tower From Brittle And Bromides.

- HCL Absorption

- HBr Absorption

- Washing Columns

- Liquid – Liquid Extraction

- Distillation / Rectification Columns

Operating Conditions:

- Temperature : -100°C to 200°C

- Pressure : Full Vacuum to 6 Kg / Cm2

Constriction:

- Shell : CS / SS

- Lining Thickness : 1.5 mm to 6 mm HDPE / PP / PVDF / ETFE / PFA / PTFE

Column & Tower Internals:

- Packing Support Plate

- Hold Down Grid

- Distribution

- Redistribution

- Dip Pipe – PTFE

- Mist Eliminator – PP, PVDF, ETFE, PFA

- Random Packing Like, Pall Ring, Intelox Saddle In PP, PVDF, PFA

- PTFE Structured Packing

- Gasket – PTFE Enveloped

Column/ Tower Size:

- From 200 mm to 2500 mm up to 5000 mm length section

PTFE Structured Packings

PTFE Lined Column Internal